601.764.4131

601.764.4131

- Home

- Industries Served

- Hydraulic Systems

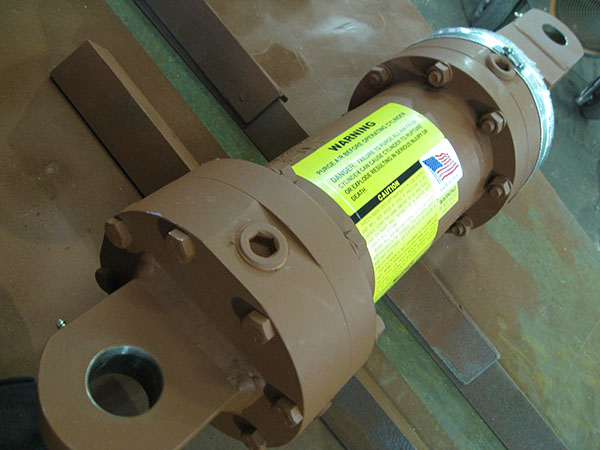

Cylinders Manufacturing for Hydraulic Systems

HSI Corporation has unique experience building cylinders for special applications. Often times, custom cylinders like these often require precise engineering designs and high strength materials. Rigorous testing is needed to ensure performance and safety in the field. HSI has over 40 years of experience meeting customers’ requirements by manufacturing these type cylinders.

- Custom sizes up to and above 36" bore

- Stroke lengths 40' and longer

- Designs up to 10000 psi working pressure

- Total weights can often reach nearly 25,000 pounds

- High yield carbon or alloy steel outer tubes

- .001" minimum chrome plated carbon or alloy steel rods

- Duplex chrome plating, as well as nickel/chrome plating available

- Options for ductile iron or bronze inlaid steel rod glands

- Cushioning at both ends of stroke

- Mounting alternatives include trunnion mount, clevis, pineyes, or lugs with spherical bearings

- Custom options for ports and integrated valves

- Diverse preferences for seals due to temperature or heavy duty usage

- Linear transducers, proximity switches, and sensors available

- Extensive pressure testing

- Finished cylinder is sandblasted and painted to customer specifications

- Hydrostatic testing data packets and material test reports available

- Seal kits available for quick shipment

- Short manufacturing lead times

HSI has built large bore cylinders for many special applications. We have the knowledge & experience required.